Ink Viscosity too Low, Not totally Dried

Problem: In the actual production process, printers often like to lower the viscosity of the ink to improve efficiency and fluidity. Although it can solve the printing adaptability & improve the efficiency, but it will cause the solvent in the ink to penetrate into the release layer and increase the difficulty of volatilization. As a result, the solvent finally were sealed in the inner layer, the release layer and the ink layer are miscible. After hot stamping, when we peel off in cold, we'll need to peel off the bottom layer together with the base layer. The phenomenon shows that the tearing is very tight, and the surface is very rough, the smell is pungent, and even the color remains.

Solution: increase the viscosity of the ink, strengthen the baking guarantee. In factories with conditions, one printing and one baking can be used to ensure every layer get totally dried.

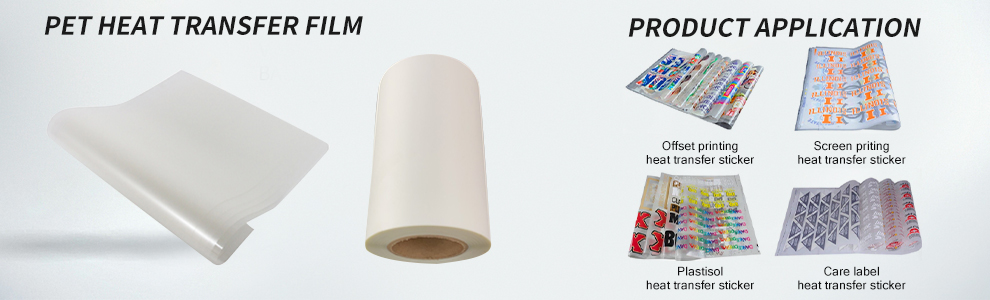

Products Category

Products Search